Understanding the Telemetry & Machine Telematics

Telemetry refers to an automated collection and transmission of data from machines to a centralised system. In construction, machine telematics involves tracking key parameters like equipment location, operating hours, fuel consumption, engine health, and maintenance status.

However, these insights are transmitted in real time, enabling contractors and fleet managers to monitor their machines remotely. Telematics systems help eliminate guesswork by providing precise data, allowing construction companies to improve efficiency, reduce costs, and enhance safety across job sites.

What Is KOMTRAX?

KOMTRAX India is Komatsu's proprietary machine monitoring and telematics system. It is mostly installed on Komatsu construction and mining equipment and continuously collects operational data.

Most of these informations are primarily sent to secure servers, where users access it via online dashboards or mobile platforms.

In the Indian market, KOMTRAX India, a system from Komatsu India Private Limited, has become a critical tool for contractors managing large fleets across various project locations.

1. Improving Equipment Utilisation

The most significant ways telematics is changing construction sites is by improving the equipment utilisation. Construction companies often struggle with underused or idle machines, resulting in unnecessary capital and operational costs.

With Komtrax, managers can monitor the following.- Idle time versus productive time

- Machine working hours

- Location and movement of equipments

This data primarily helps you identify inefficiencies and reallocate machines where they are needed most. For large infrastructure projects across India, KOMTRAX India enables more effective planning and ensures every machine delivers maximum value.

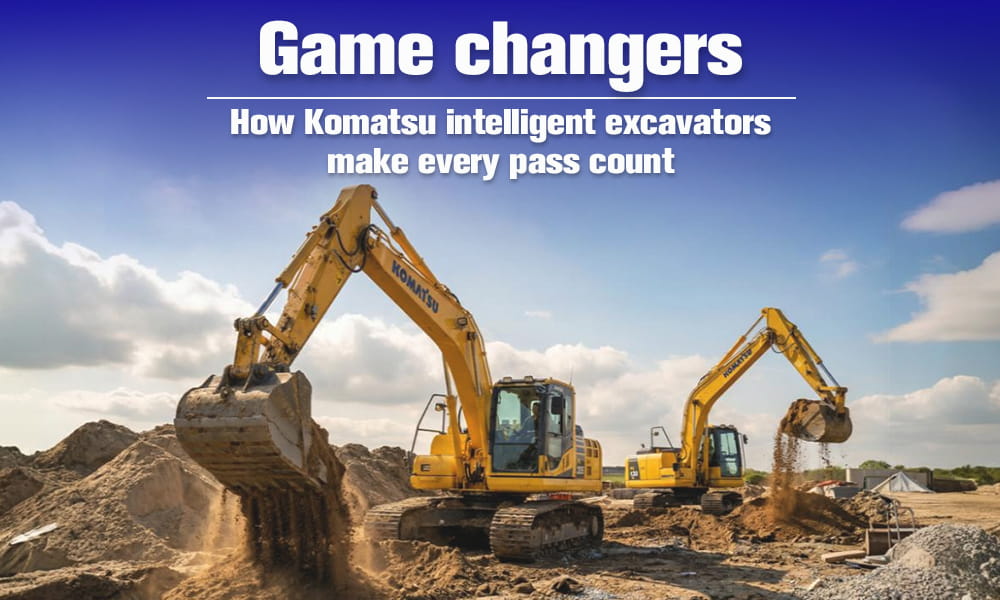

2. Predictive Maintenance & Reduced Downtime

At times, unexpected equipment breakdowns do cause primary project delays and financial losses. At the same time, Telemetry and machine telematics address this challenge through predictive maintenance.

KOMTRAX do monitor the following.- Oil pressure and temperature

- Engine performance

- System alerts and fault codes

Thus, by analysing this data, the maintenance team can detect potential issues before they turn into major failures.

According to Komatsu India Private Limited experts, scheduled maintenance becomes more accurate by reducing unplanned downtime and extending equipment lifespan. This kind of proactive approach has become a real game-changer for construction companies that rely primarily on tight project schedules.

3. Enhanced Fuel Efficiency & Cost Control

In general, fuel costs account for a significant portion of construction operating expenses. As a result, Telematic systems like KOMTRAX India provide detailed insights into fuel consumption patterns, helping companies identify wasteful practices.

Through KOMTRAX India, fleet managers can deal with the following.- Identify excessive idling

- Track fuel usage per machine

- Compare performance across numerous operators

With this information, companies do implement fuel-saving strategies, train operators more effectively and reduce overall operational costs without compromising productivity.

4. Better Safety & Compliance on Job Sites

Safety is a top priority on construction sites, and machine telematics plays a critical role in improving it. KOMTRAX aids in monitoring machine behaviour, ensuring equipment is operated within safe parameters.

Some of the key safety benefits include the following.- Alerts for abnormal machine usage

- Monitoring operating conditions

- Ensuring timely maintenance for safe operation

By reducing mechanical failures and encouraging responsible equipment use, telematics systems contribute to safe working environments for both operators and site personnel.

5. Real-Time Visibility for Smarter Decisions

While construction projects do involve multiple sites spread across broad geographic areas, managing it efficiently requires real-time visibility.

At times, KOMTRAX provides centralised access to fleet data, enabling project managers to:- Monitor multiple job sites remotely

- Make both quick and informed decisions

- Respond faster to all sorts of operational issues

For large-scale contractors who use the KOMTRAX India technology, this level of transparency improves coordination and ensures that projects stay on schedule and within budget.

6. Supporting Sustainable Construction Practices

Sustainability is becoming increasingly crucial even in the construction sector. Telematics helps companies reduce their environmental impact by optimising fuel use, minimising idle time, and ensuring proper machine operation.

By taking advantage of KOMTRAX data, construction firms can lower emissions, reduce fuel waste, and align with modern environmental standards, which is an important consideration even in today's infrastructure development.

Key Takeaways

Telemetry and machine telematics revolutionise construction sites by transforming real machine data into actionable insights. As a result, systems like KOMTRAX India are aiding construction companies to improve productivity, reduce downtime, enhance safety, and control costs more efficiently than ever before.

With the growing adoption in markets like KOMTRAX India, telematics is no longer a luxury; it is essential for construction businesses aiming to remain absolutely competitive in a fast-growing industry. Since technology continues to advance, machine telematics will undoubtedly play a huge role in shaping the future of construction operations.