What Are Ground Engaging Tools (GET)?

Ground Engaging Tools (GET) are the replaceable parts of the earthmoving and excavation equipment that directly interact with rock, soil, and other materials. According to Komatsu India's experts, these components are most likely to experience the most abrasion, impact, and wear. They include items such as bucket teeth, adapters, cutting edges, end bits, ripper points, side cutters, and more.

For specific machines such as excavators, dozers, wheel loaders, graders, and backhoes, GET is critical for efficient material handling. Komatsu offers a complete lineup of GET that certainly align with their machines' engineering standards, ensuring optimal fit, strength, and durability.

Why GET Matters for Komatsu Machines

Using high-quality, machine-specific, especially Komatsu GET, can provide several advantages that impact overall operating costs and machine performance.Improved Digging Efficiency

Trenching, digging, loading, and scraping all rely heavily on the sharpness and strength of the GET. Certainly, worn-out or low-quality GET can rapidly reduce penetration ability, causing the machine to work harder than necessary.

Komatsu's engineering ensures that its GET-equipped machines can penetrate material with minimal resistance. It definitely results in the following.

- Reduced fuel consumption

- Faster cycle times

- Less strain on hydraulic systems

Furthermore, equipment owners often notice immediate performance improvements by using proper GET for all their machines.

Ground Engaging Tools for Excavators

Komatsu's ground engaging tools perform some of the most demanding tasks on mining and construction sites. This is why ground engaging tools for excavators must be rugged, precise, and reliable. Komatsu GET for excavators consists of bucket teeth, adaptors, wear plates, and side cutters, which are engineered for maximum durability.

Therefore, by using the right GET for excavator, you can definitely ensure the following.

- Strong digging force

- Cleaner custs

- Less bucket wear

- Longer intervals between maintenance

It is specifically essential when working in complex, abrasive, and certain rocky conditions.

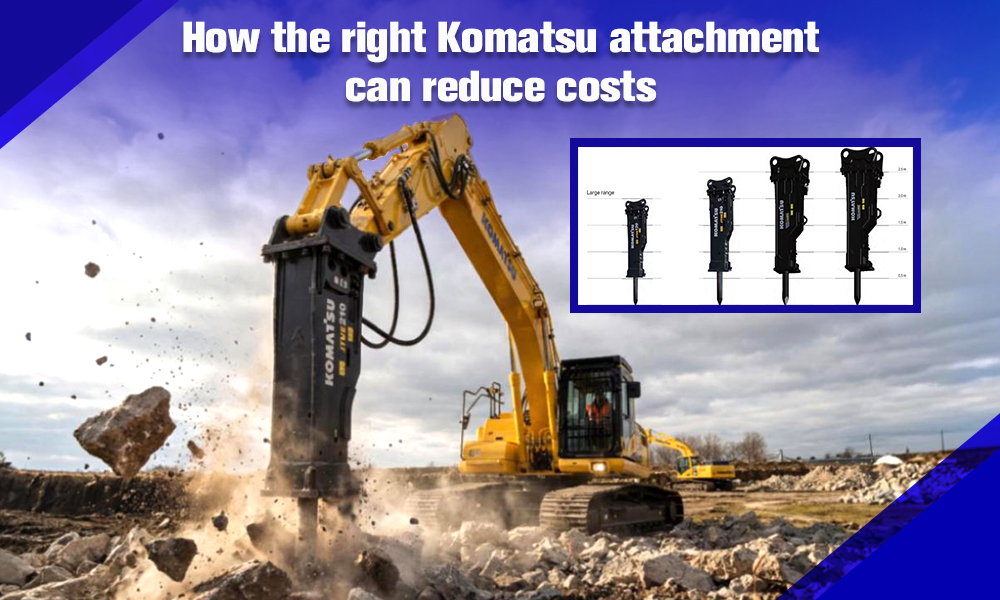

The Importance of Komatsu Bucket Teeth and Adapters

Among the GET components, Komatsu bucket teeth and adapters are among the most critical. Bucket teeth are the first point of contact with the ground, and their shapes determine how efficiently material can be broken or scooped.

Komatsu offers a wide range of bucket teeth, including:

- Chisel tooth for tougher digging

- Penetrating teeth for compact soil

- Heavy-duty rock teeth for mining and quarry applications

Adapters that connect the teeth to the bucket must withstand enormous force. Certainly, genuine Komatsu adapters are precision-engineered to prevent twisting, loosening, and cracking. Some common problems when using generic alternatives are: This reliability protects the bucket, reduces downtime, and enhances safety.

Komatsu Cutting Edges and End Bits: Essential for Dozers and Loaders

Full bulldozers, graders, and wheel loaders, Komatsu cutting edges and end bits play a critical role in shaping, levelling, and pushing material. According to Komatsu India experts, these components are constantly exposed to abrasive surfaces, making material quality and manufacturing precision key factors in wear life.

Komatsu cutting edges and end bits offer the following.

- Enhanced penetration into dense or compacted material

- Superior wear resistance

- Greater surface control for grading and levelling

- Lower risk of unnecessary machine strain

Using genuine components definitely ensures each pass is more effective, reducing fuel use and improving productivity.

1. Cost Efficiency Through Longer Wear Life

Whereas some operators indeed opt for cheaper, generic GETs, as these often wear out quickly, break prematurely, and add stress to the machine. Komatsu manufactures GETs using advanced alloys and heat-treatment processes that significantly extend wear life.

Longer-lasting GET provides the following.

- Lower operating cost per hour

- Fewer replacements

- Reduced downtime

- Better machine protection

In the long run, Komatsu GET delivers superior value as compared to generic replacements.

2. Safety and Machine Protection

Worn-out and poor-quality GET can always lead to structural damage, unexpected breakage, and even accidents. Genuine Komatsu GETs are designed to distribute stress evenly, reduce vibration, and ensure a secure attachment system. This not only protects the bucket and linkage but also boosts the operator's confidence.

Bottom Line Ground-engaging tools are small components with a significant impact on the machine's performance. For Komatsu machines, using higher-quality, precisely engineered GET, such as Komatsu bucket teeth and adapters, Komatsu cutting edges and end bits, and the full range of ground engaging tools for excavators, is critical for maximising efficiency, equipment life, and productivity. By choosing Komatsu, GET definitely ensures your machines cut cleaner, dig deeper, and last longer-delivering consistent performance in every job, and every day.Bottom Line

Ground-engaging tools are small components with a significant impact on the machine's performance. For Komatsu machines, using higher-quality, precisely engineered GET, such as Komatsu bucket teeth and adapters, Komatsu cutting edges and end bits, and the full range of ground engaging tools for excavators, is critical for maximising efficiency, equipment life, and productivity.

By choosing Komatsu, GET definitely ensures your machines cut cleaner, dig deeper, and last longer-delivering consistent performance in every job, and every day.

FAQs

1. What types of GET does Komatsu offer (teeth, adapters, edges, end bits, shanks)?

Komatsu offers a comprehensive range of Ground Engaging Tools designed to meet the performance requirements of its machines. The primary GET categories offered by Komatsu are as follows.

- Bucket Teeth This is required for penetration, breaking, and material loading.

- Adapters Secured mounting components for bucket teeth.

- Cutting Edges Cutting edges are used on dozers, graders, and loaders for levelling and pushing.

- End Bits It certainly protects the blade corners and improves durability.

- Ripper Shanks & Tips Rippers, Shanks and tips are required for breaking hard soil, rock, and compacted materials.

- Side Cutters, Wear Plates, and Lip Protectors These are required for added bucket protection. Definitely, this wide variety ensures that every Komatsu excavator, loader, dozer, and grader can be outfitted with the right GET for specific job conditions.

2. How do Komatsu genuine GET improve machine productivity and fuel efficiency?

Komatsu genuine GETs are engineered to match the exact specifications of Komatsu machines, resulting in high precision, better performance, and reduced machine strain. They improve productivity and fuel efficiency through.

- Superior penetration It features sharper, stronger teeth that require less force to dig and break materials.

- Improved cycle times Indeed, faster bucket filling means more work is done in a shorter period.

- Reduced wear on key components It is the genuine GET that minimises stress on the arm, hydraulics, and the boom.

- Optimised material flow Furthermore, properly shaped GET reduces friction and enhances loading efficiency.

- Longer wear life Superior quality alloys definitely ensure fewer replacements and less downtime.

When combined, most of these factors enable the machine to operate smoothly, consume less fuel, and deliver the maximum output.

3. Where can you purchase Komatsu genuine GET in India?

You can definitely buy Komatsu genuine GET across India through our official website and authorised Komatsu dealers and service centres nationwide. You can avail yourself of our certified Komatsu parts distributors specialised in construction and mining equipment.

As a result, Komatsu India’s official customer support guides the nearest approved supplier.

- Komatsu genuine parts counters at major job-site support hubs

- Do ensure you purchase from authorised sources to avoid counterfeit or low-quality GET that may cause equipment damage and void warranties.

4. How do I know which bucket tooth or adapter fits my Komatsu excavator?

Therefore, selecting the correct bucket tooth or adapter for your Komatsu excavator depends on factors such as model number, application, soil conditions, and bucket design. To identify the correct GET:

Definitely, refer to your machine’s parts manual for exact tooth and adapter specifications. Do check out the existing adapter or tooth markings, which often include size or series codes. Consult our authorised Komatsu dealer, who can verify compatibility using your machine’s serial number.

Share details such as job type (rock, earth, quarry, demolition) so the dealer can recommend the appropriate tooth profile. Avoid guesswork; using the wrong tooth or adapter can lead to poor fitment, breakage, or uneven wear. Komatsu experts ensure you get the right GET that fits perfectly and delivers maximum digging performance.