The construction industry has consistently led the way in technological advancements, adapting to the need for improved efficiency, safety, and sustainability. As we progress into 2025, one of the critical innovations is the rise of the advanced rockbreaker equipment. These cutting-edge tools transform overall construction operations. They significantly enhance productivity and minimize environmental impacts.

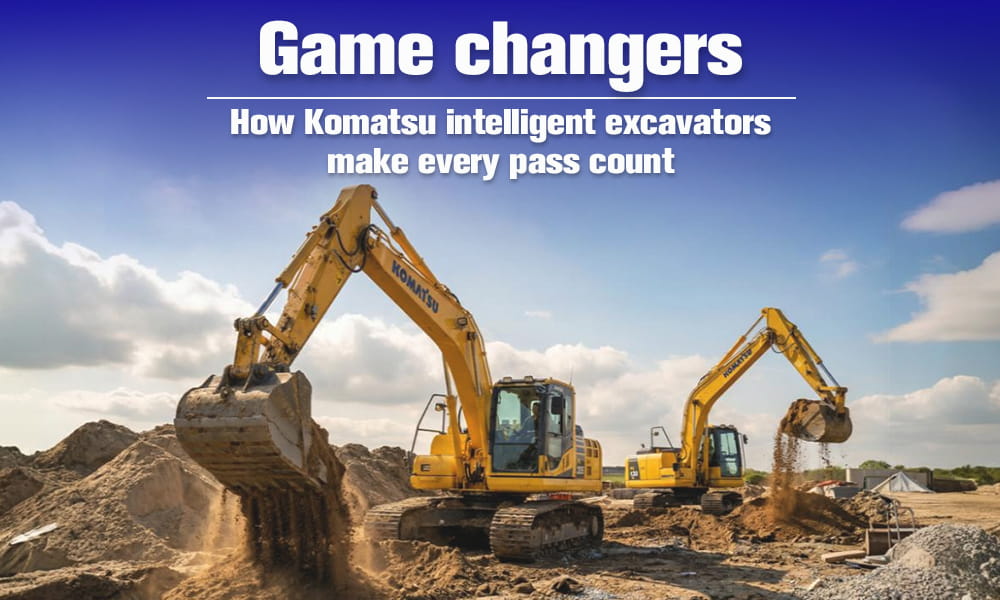

Hydraulic rockbreaker machines are critical for construction jobs that involve the demolition of rock or concrete. As their name suggests, they are specially designed to break rocks into manageable sizes for safe and efficient transport. These machines are generally found on construction sites where significant demolition tasks are necessary.

How Exactly Do Rockbreaker Machines Help in Construction Projects?

Komatsu India manufactures a hydraulic breaker, also known as a hydraulic hammer. It is a construction machine primarily attached to excavators, backhoes, skid steers, and mini-excavators. Generally, it features an extending arm with a hammer at its end, which delivers repeated impacts to break rocks or concrete into manageable pieces. It consists of the hammer, which crushes hard materials, and the arms that support it.

These machines come in different sizes, ranging from miniature handheld versions to large, robust units that are mounted on a specific construction vehicle, depending on the particular operational need.

Top Features That Make Advanced Rockbreaker Machines Stand Out

Accurate Design and Enhanced Power

A modern hydraulic rock breaker is designed using advanced components and materials, resulting in improved strength and accuracy.

Upgraded piston and hydraulic cylinder design

The upgraded piston and hydraulic cylinder design enables these machines to produce more powerful strikes while consuming less energy. This type of precision is crucial for several mining activities that need precise breaking to reduce waste and improve ore recovery.

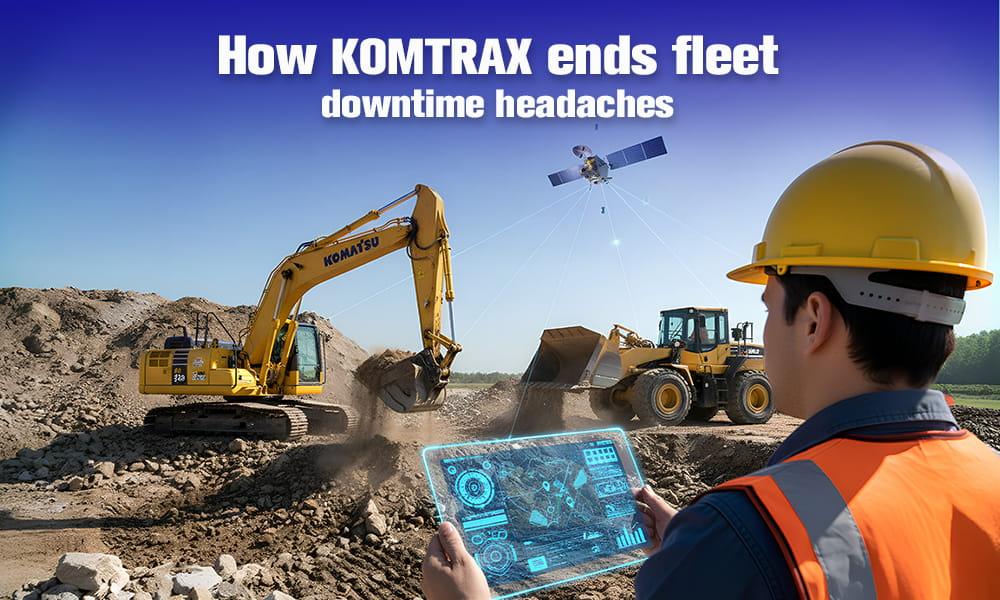

Smart Technology and Automation

A significant trend is the adoption of automation and advanced technology. Most contemporary rock breaker is designed for excavators. They come with sensors and control systems that enable real-time monitoring and adjustment to various performance metrics. This type of automation reduces the need for human involvement. It enhances safety by reducing exposure to hazardous conditions and improving operational efficiency.

Reduced Maintenance and Enhanced Durability

The advanced hydraulic rock breaker is designed for durability, incorporating innovative materials and construction methods that enable it to withstand more challenging conditions found in construction settings.

These advancements result in extended periods between maintenance and repairs, lowering downtime and operational expenses. The improved reliability significantly benefits construction operations by facilitating stable and predictable production output.

Why Hydraulic Breakers Are the Best Choice for Heavy Work?

The hydraulic breaker manufactured by Komatsu offers numerous advantages over traditional mechanical and pneumatic breakers. Some of its key benefits include:

Power and Efficiency

It delivers high-impact energy by enabling quicker and more efficient demolitions.

Precise Control

The hydraulic rock breaker is engineered precise control over both impact force and frequency, enabling users to adapt to a wide range of materials and work environments.

Reduced Vibration

It is the hydraulic rock breaker that is engineered to reduce the vibration transmitted to the base machine. Furthermore, it reduces operator fatigue and enhances comfort during use.

Easy Maintenance

Hydraulic rock breakers require minimal maintenance because of their simple design and fewer moving components compared to mechanical or pneumatic options. Furthermore, routine maintenance involves inspecting the chisel, verifying hydraulic connections, and ensuring adequate lubrication to prevent wear and tear.

Technology Trends in the Construction Industry

The adoption of the hydraulic breaker is a significant technological shift and transforms the construction industry. As we enter 2025, numerous technological trends in the construction industry are impacting contemporary construction practices.

Automation and Remote Operation

Automation is being significantly adopted in construction operations. The use of remote-controlled and autonomous machinery, such as rock breakers, is enhancing operational efficiency and reducing the need for human involvement in hazardous environments.

Data Analytics and AI

Artificial intelligence and data analytics are revolutionizing construction operations by facilitating predictive maintenance, enhancing equipment efficiency, and streamlining decision-making processes.

Energy-Efficient Technologies

As sustainability becomes increasingly important, the construction sector is implementing energy-efficient technologies to reduce its environmental impact.The hydraulic rock breaker is evolving to be more energy-efficient. This helps reduce energy use in demanding construction activities.

The Future of Rockbreaking Technology

The future of the rock breaker technology holds enormous promise for advancements. As rapid progress continues in AI, robotics, and materials science, the next generation of rock breakers is expected to be more efficient, safer, and environmentally sustainable.

One of the potential areas for growth is the integration of rock breakers with other automated construction machinery by creating fully autonomous systems.

Final Thoughts

The rock breaker is at the forefront of revolutionizing the construction industry in 2025. Its contributions to efficiency, safety, versatility, and sustainability are reshaping the rock breaker industry, with the technology at the forefront.

As technology continues to advance, the role of hydraulic breakers will become more integral to the future of the construction industry. As construction companies strive to stay ahead in an increasingly competitive industry, they invest in advanced hydraulic rock breakers; it is no longer a choice but a strategic necessity.

Therefore, by embracing these cutting-edge machines, the construction industry can look forward to a future characterized by greater efficiency, enhanced safety, and a more substantial commitment to sustainable practices.