Motor graders play a crucial role in the construction and infrastructure development sectors. This heavy machinery stands out as a key player in road construction. We at Komatsu India design versatile motor graders for grading and leveling surfaces, making them ideal for creating smooth and even roads.

If you are searching for the finest motor graders, we can provide you with the best. In this blog, we have discussed the role of grader machines, their various features, and primary benefits in road construction.

What are motor graders?

A motor grader is a heavy construction machine equipped with a long blade that is used to create a flat surface during the grading process. The long blades of motor graders are commonly referred to as the moldboard, which is mounted between the front and rear axles. This blade is adjusted to various angles and positions to get the desired grade. Our motor graders are typically used in the construction and maintenance of roads. The primary aim of this heavy machine is to maintain a fine and even grade of materials, such as soil or gravel, in order to make the area smooth enough.

Main features of a motor grader

As one of the leading heavy machine manufacturers, we include high-end features within our motor graders. Here are the main features of a motor grader used for road construction:

Adjustable moldboard (blade)

The blade can be moved up, down, tilted, rotated, and shifted side-to-side for precise grading and shaping of surfaces.

Articulated frame

Allows the front and rear of the grader to pivot independently, improving flexibility in tight spaces and around curves.

Hydraulic controls

Enable smooth, accurate control of the blade and attachments, enhancing operator efficiency and precision.

Operator cab with enhanced visibility

Our motor grader machines are designed with large windows and ergonomic controls to give the operator a clear view and a comfortable working environment.

Scarifier

A front-mounted attachment used to break up compacted soil or surfaces before grading.

Benefits of Using a motor grader

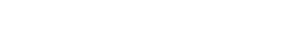

Motor graders bring an ample amount of benefits in road construction. Here’s how our modern motor graders make each road construction project successful:

Precision and accuracy

Our motor graders are designed to create smooth, level surfaces with high precision. They are ideal for fine grading and shaping road foundations to ensure long-lasting quality. In return, they reduce the likelihood of uneven surfaces and structural weaknesses.

Versatility in application

Our motor graders are capable of performing multiple tasks such as grading, spreading, cutting ditches, and shaping shoulders. They are useful in both large-scale highways and smaller rural or urban roads. With modern designs, each motor grader can handle gravel maintenance, snow removal, and surface finishing.

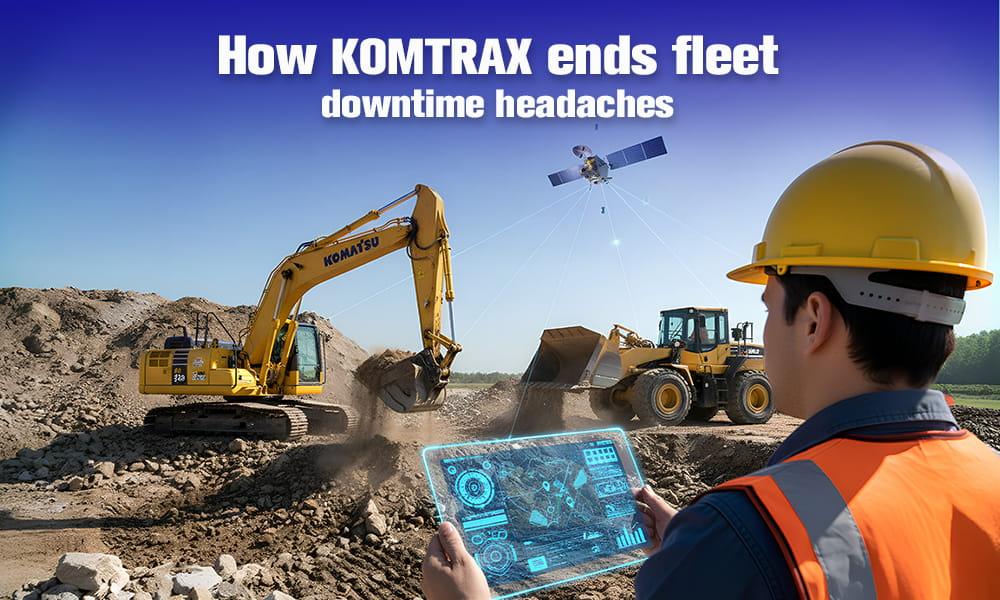

Advanced technology integration

Modern grader machines feature GPS systems and automated controls for enhanced accuracy. Digital displays and controls help operators monitor blade angles and grading depth in real-time.

Improved efficiency and productivity

Our efficient motor graders speed up project timelines by reducing the need for multiple machines. They will enhance workflow by combining grading and leveling into one process. Furthermore, our machines contribute to lower labor and fuel costs.

Increased safety and reduced maintenance

Reliable and stable design of our motor graders reduces the risk of job site accidents. They create a stronger road base, minimizing long-term repair needs. Precise engineering of motor grader machines improves the overall durability of constructed roads.

How to choose the right motor grader for your project

When initiating a road construction project, it is essential to choose the right motor grader. Consider the following factors before selecting a motor grader:

Project requirements

Determine the scale and scope of your project. For large-scale roadworks, high-horsepower graders with wide moldboards are ideal. Smaller projects may require more compact and efficient machines.

Engine power and blade size

Engine power affects grading efficiency. Projects needing deeper cuts or heavy material movement demand higher horsepower. Choose a blade width that matches the job’s surface area and required precision.

Terrain and site conditions

Assess the working environment. Rough or uneven terrain may need a grader with all-wheel drive and enhanced traction. Consider ground clearance and machine stability as well.

Operator comfort and control systems

A comfortable operator is more productive. Look for graders with ergonomic cabins, adjustable controls, and advanced control systems like GPS or automatic blade control for accuracy.

Budget and maintenance support

Balance cost with performance. As one of the leading machine manufacturers, we ensure the grader fits your budget but also offers long-term value. Availability of local service, spare parts, and manufacturer support is critical. Selecting the right motor grader ensures efficient project execution and long-term savings.

Conclusion

When it comes to motor grader machines, Komatsu India stands out. With a commitment to sustainability and innovation, we have designed our machines for superior road construction. Incorporating Komatsu India’s motor graders in your road construction projects will be cost-effective and time-efficient. With our versatile machine, you will be able to cater to multiple and complex construction projects. We at Komatsu India will provide you with the best solutions to your project needs.