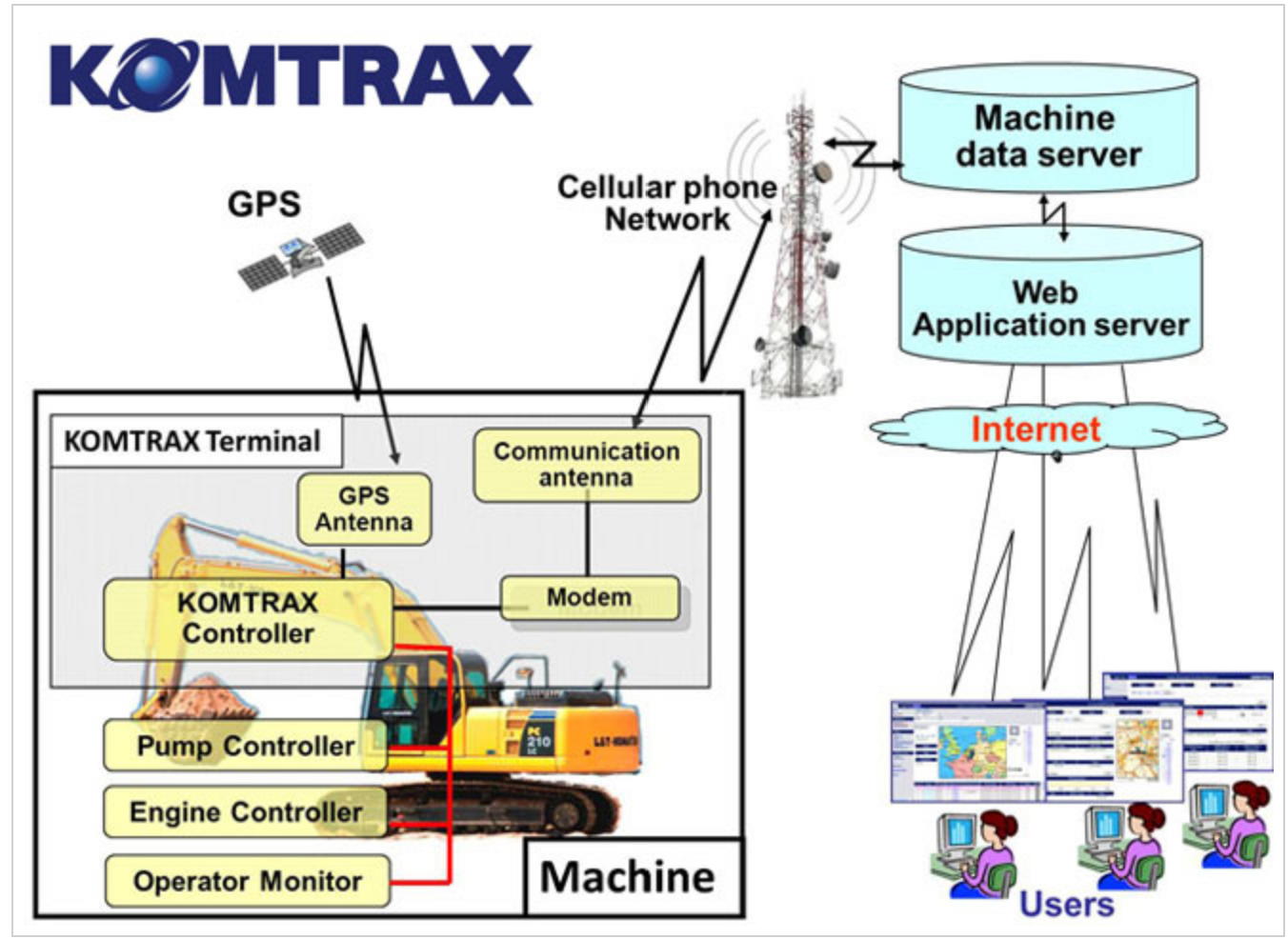

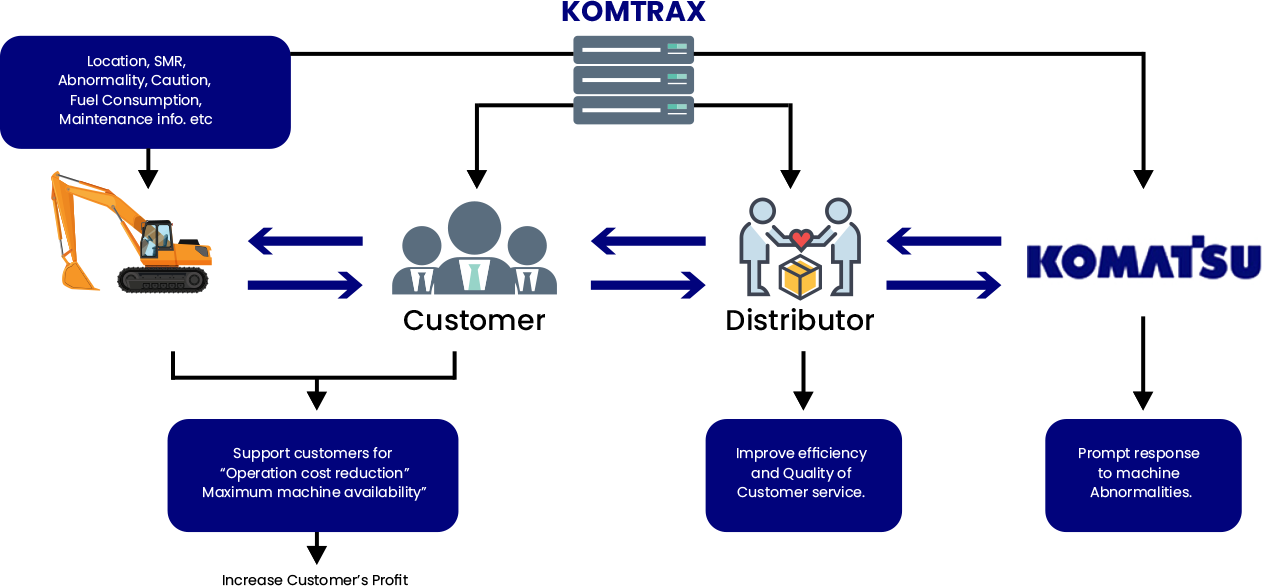

KOMTRAX is a wireless machines tracking system developed by Komatsu Limited to increase your machine productivity by giving you fast and easy internet access to key machine information.

KOMTRAX gives you the power and knowledge to help you make fact-based, basic and strategic business decisions regarding your machines and their operations. This pays off in increased productivity and availability.

Next Generation Komtrax(NGK) is Komatsu’s complimentary remote monitoring system. KOMTARX harnesses satellite and mobile based Information Communication Technology (ICT) data to allow you to monitor the location, health, and performance of every machine in your fleet - whether a single machine or hundreds of units.

KOMTARX is completely compatible with the latest smartphones, tablets, and computers, ensuring you have access to your information on any device at any time.

Wherever your equipment is operating in India, KOMTARX constantly checks operational conditions and status to help you maximise machine safety, productivity, uptime, and availability.

You can also customise your own interface to meet your own fleet and project management requirements, so it's easy to track and assess the performance of each machine.

And because KOMTRAX constantly monitors the location of each machine, it's a vital tool in keeping track of where they are.

Using an interactive map, you can easily access telemetry data on each of your KOMTRAX-equipped machines at a glance on your computer or your mobile.

Easy Machine Management: Customers can get their own machines records automatically with KOMTRAX. Customers can get summarized data of each machine like Working Hours, Actual Working Hours, Actual Working Ratio, Fuel Consumption, E Mode Ratio, Total Working Hours, Avg. Working Hours, and Total Fuel Consumption etc. Customers can get each machine's current status, the location, the SMR, the working status, the amount of fuel and the water temperature with one screen.

Preventing Emergency Breakdown: Customers can get cautions and periodical maintenance information of their machines automatically with KOMTRAX. Information like date & hours of last maintenance and hours to next maintenance etc, help customers maintain their machines well.

Have you ever experienced unauthorized use of your machines?

Your machines may be being used with out your knowledge. The KOMTRAX also allows you to keep track of your machine operating status. You do not have to worry about whether an operator is doing his (or her) duty while in control of an expensive machine. Customers can watch every machine's daily working hours easily. Therefore you can realize the operator's working status.

The KOMTRAX allows you to monitor the location and activities of your machine. If the customer has a lot of machines, the map of the machine's locations and each machine's data will help the customer make the machine's distribution plan. KOMTRAX will give a very sophisticated screen for customers compared with competitors.This benefit is very useful for rental company customers. KOMTRAX screen may improve the fleet management dramatically.

A log of working hours and machine load history can help you to estimate the degree of deterioration of your machines. Logs of all maintenance performed on your machines enable you to monitor the extent to which they have been appropriately used.

Protects your machines from fuel theft, KOMTRAX provides fuel consumption data and fuel tank levels, Sudden decrease of fuel level shows the possibility of fuel theft. The information KOMTRAX reports will vary by machine model for Komatsu Equipment.

| Service Meter Reading | Location | Movement generated position report |

| Actual fuel consumption | Average hourly fuel consumption | Attachment working hours |

| High water temperature during the day’s operation | Out of area alerts | Digging hours |

| Maintenance reminders / notifications | Travel hours | Breaker usage hours |

| Actual working hours (Engine on time less idle time) | Eco-mode usage hours | Load frequency(Hours spent in four different load levels determined by pump pressure or engine torque. |

| Operation hours in each work mode(Economy, Power, Breaker, Lifting) | Operation map(Time of day the engine was on/off) | |

| Hoisting hours | Residual fuel level | |

| Hydraulic relief hours | Dashboard hours |

Contact your local Komatsu Distributor to find out the specific information your machine is capable of reporting.

Komatsu's KOMTRAX Plus (formerly VHMS) provides the means to monitor the health of major components on large machines, enabling the remote evaluation of the machine's condition and operations. This system has been designed to reduce repair costs and maintain optimal machine availability by helping to prevent unscheduled downtime.

The KOMTRAX Plus system enables downloaded machine data to be transmitted via the Internet and reviewed by Komatsu and Distributor service personnel.

KOMTRAX Plus reports vital information in several areas. The operating conditions of machines and their service meters can be monitored. Trends, when graphically displayed as change-over-time, enable remedial action before breakdowns occur. Fault and event codes that are displayed on the machine's monitor panel are recorded for future reference. Other data types include engine performance, real-time fault analysis, and machine operation history.

KOMTRAX Plus provides you with the means to monitor machine conditions, helping you achieve maximum productivity and utilisation. Some of the key features and benefits include: